News

Advantages analysis and application of microporous aeration technology

Microporous aeration technology uses microporous pipes to aerate the bottom of the pond to increase oxygen. The dissolved oxygen is evenly distributed and the oxygen increasing area is wide. When the power of the main engine is the same, the oxygenation capacity of the microporous aerator is three times that of the vane type aerator.

1、 Principle

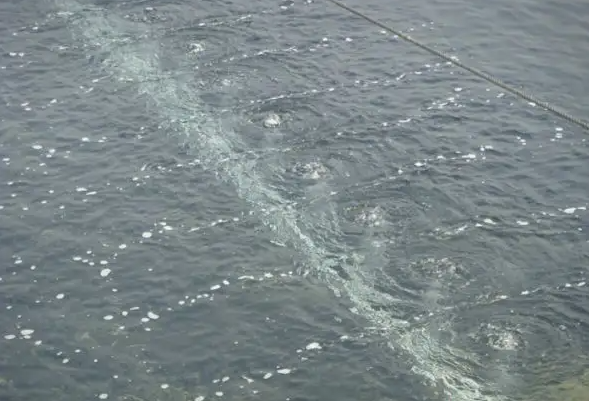

Roots blower is used to send the air to the gas transmission pipeline, and the gas transmission pipeline sends the air to the microporous pipe. The microporous pipe disperses the air into the water in the form of microbubbles. The microbubbles float upward from the bottom of the pool. Under the action of the high oxygen partial pressure of the gas, the oxygen is fully dissolved in the water, which can also cause the rotation and up and down flow of the water flow. The up and down flow of the water flow will bring the oxygen rich water in the upper layer to the bottom layer, At the same time, the rotating flow of the water will diffuse the oxygen rich water around the microporous tube outward to realize the uniform oxygenation of the pool water.

2、 Advantages

1. Power saving. The new blower has wide pressure, simple structure, convenient maintenance, long service life and small vibration. The practice has proved that the underwater aeration has a good effect of increasing oxygen. Compared with the traditional aeration method, it achieves the same effect and can save 60 ~ 80% of electricity. A 2.2 kW high-performance oxygen increasing equipment with an effective oxygen increasing water surface of 30 ~ 40 mu.

2. Improve the ecological environment of aquaculture water.

The bubble flow generated at the bottom of the water body by aeration is wide. Generally, when the water depth is 2 meters, the atomized bubble can diffuse to 3-4 meters; An underwater oxygen increasing disc with a diameter of 80 cm generates a vortex bubble flow, and the effective oxygen increasing area is 25 square meters. Sufficient air flow in contact with a large area of water surface can ensure that the dissolved oxygen at the bottom of the water body is 6.5 mg / L, accelerate the oxidation and decomposition of harmful substances such as organic matter and nitrite deposited at the bottom of the water body, and bring harmful and toxic gases out of the water surface, so as to improve and stabilize the water quality, create a suitable growth environment for fish, shrimp and crab, and reduce the occurrence of diseases.

3. It is conducive to high-density breeding. Aeration is the static bottom oxygenation. The effective dissolved oxygen of the whole water body is sufficient, which improves the activity ability of the breeding objects in the space of each layer of the water body, increases appetite, shortens the breeding cycle, and creates conditions for increasing the biological load of the water body. For example, when culturing Penaeus vannamei, the underwater aeration method is adopted. The stocking density per mu can be 80000 to 100000, and the output can reach about 1000 kg. Four big fish can be raised twice as much as traditional stocking. Because the oxygen increasing method can improve and stabilize the water quality environment, reduce the occurrence of stress and other diseases, improve the survival rate, increase appetite and growth speed.

4. Easy to use. Fans with different power can be configured for different water surface areas. One fan can implement double pond or multi pond oxygenation. The connection and replacement of main pipe and branch pipe are convenient.

5. No leakage in water. Compared with the traditional aerator, the microporous aerator is arranged in the water and the motor is on the shore, so there is no possibility of leakage in the water.

6. It will not be entangled by garbage in the water to damage the motor and affect oxygenation.

3、 Structure and installation

The microporous oxygen increasing facilities are mainly composed of main machine (motor), roots blower (rotation speed 1400 RPM), air storage buffer device, main pipe (PVC plastic pipe), branch pipe (PVC plastic pipe or rubber hose), aeration pipe (microporous nano aeration pipe), aeration disk, etc.

The belt of the main machine (power matched with the roots blower) drives the roots blower. The roots blower is connected to the gas storage buffer device, the gas storage buffer device is connected to the main pipe, the main pipe is connected to the branch pipe, and the branch pipe is connected to the aeration pipe. There are two specific installation methods.

1. Disc mounting method

Each mu is equipped with a blower with a power of 0.1-0.15 kW. The tray can be 4-6 mm diameter reinforcement. The aeration pipe is fixed on the frame. The total length of the tray is 15-20 meters. 3-4 trays are installed per mu. The total length of the tray is 30 meters. 2-3 trays are installed and fixed, 10-15 cm from the bottom of the tank.

2. Strip installation method

Each mu is equipped with a blower with a power of 0.1kw. The total length of the aeration pipe is about 60m, the pipe spacing is about 10m, the height difference is not more than 10cm, and it is fixed, 10-15cm from the bottom of the tank.

4、 Usage:

According to the law of dissolved oxygen change in water body, determine the time and period of startup and oxygenation. Generally from April to may, start the machine at midnight in rainy days; From June to October, the machine will be turned on for 2-3 hours in the afternoon and 2-3 hours before sunrise. It will be turned on from 21:00 to 22:00 at night in continuous rainy or low-pressure weather and will last until noon of the next day; Start up frequently in the later stage of aquaculture to promote the growth of aquaculture objects. Carry out dissolved oxygen detection if possible and start the machine in time to ensure that the dissolved oxygen in the water body is 6-8 mg / L.

5、 Maintenance

1. Replace the microporous tube in time if it is found to be broken.

2. If the algae attach too much and block the micropores, pat it gently after one day's exposure to the sun, shake off the attachments, or soak it in 20% detergent for 1 hour, then clean it, dry it and reuse it.

3. Ensure that the power box does not leak electricity.

4. Roots blower shall be lubricated and maintained regularly.

5. Rust prevention is required in rainy season.

6. In the high temperature season, it is necessary to prevent exposure to the sun, and a shed can be built.

7. If the interface is loose, fix it in time.

8. At the end of the production cycle, it shall be removed and stored in the warehouse.

Welcome to contact:+8618013418091(Whatsapp/Wechat)

+8618013418097(Whatsapp/Wechat)

Alvin

Alvin hugh778

hugh778